|

|

Archway - Tower Bank |

The deposit of igneous rock known as Craster Whinstone is a great mass of basalt, having the characteristic columnar formation, and occurring as "heughs," or low hills stretching some two miles in length, a quarter to half a mile wide, and 60 feet deep along the coast of Northumberland. It is situated at a point some 25 miles south-east of Berwick, and 33 miles north of the Tyne, where it forms a natural sea-defence, a wall of enormous strength, protecting the Craster estate from erosion by the North Sea. As a stone it is extremely hard and tough, and undoubtedly has great weather resisting properties. The amount of decomposition over the rock surface is seldom more than a few inches in depth, and this indication of weather resistance is supported by local experience, for in houses of great age built of it there is not the slightest evidence of change. This characteristic moreover seems to be consistent throughout the mass, for in the quarried faces there are no soft beds or other inferior portions, such as are found where chemical decomposition is liable to occur. As a road-stone the material has always been highly esteemed locally, but as a valuable commodity for export it has in the past been extraordinarily neglected. From old records in the possession of Mr. T. W. Craster of Craster Tower, it appears that a certain quantity was shipped to London in 1772 from an ancient quarry adjoining the present workings, but now overgrown with gorse, heather, and ferns.

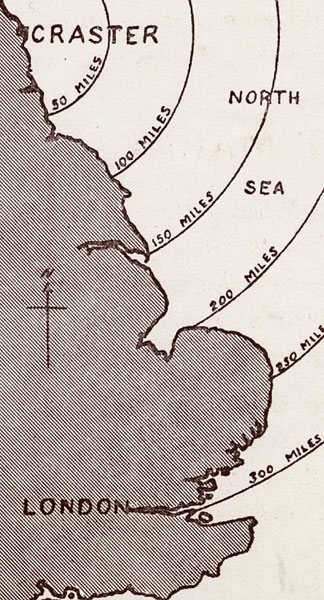

An advertisement appeared in the Newcastle Courant of the 14th March in that year: "Craster Whinstone Quarries; wanted immediately, a number of good hands that understand the dressing of the said stone for paving London streets. Apply to Mr. Dan. Craster at Preston." But, with this exception, the use has in the past been entirely local, no doubt on account of the absence of railway communication on the one hand, and the difficulty of shipping from a naturally exposed coast on the other. From the point of view of commercial geography, however, the position of the Craster Whinstone is very favourable, as it is the first sea-outcrop of hard igneous rock in any quantity that would be met with in traversing the whole of our south and cast coasts, from the Cornish quarries to Northumberland. This is a length of some 600 miles of country, over which road traffic is heavy, and the demand for hard road-stone enormous - probably over a million tons a year. The economic possibilities of such a stone in such a position seem to have been first fully realised when the construction of a small fishery harbour was commenced at Craster village in 1905, though the shipping of stone was not by any means one of the trades which it was built to foster. The construction of the harbour was undertaken by Mr. T. W. Craster, primarily for the use of the local fishermen, but also as a memorial to his brother, the late Captain J C. P. Craster, who fell in the Thibetan expedition of 1904. The harbour was to be formed by excavation out of solid basalt, an expensive undertaking, greatly facilitated by the business foresight of Mr. McLaren, a contractor and quarry owner, who offered to do this part of the work without payment in view of the value he believed the stone would represent. This offer may be said to have inaugurated the modern Craster Whinstone operations, which the opening of the harbour rapidly developed into a great trade, so that now, in three or four years, the harbour having been found too small for its business, extensions are being planned, and railway communication contemplated. Character of the Stone Craster Whinstone, geologically described, is an igneous rock of volcanic origin, or, more precisely, a basalt of hard and tough quality and high specific gravity. It gives a dark blue, close-grained fracture, and is capable of being dressed into setts, curbs and building stone. In the latter use it gives an appearance of sombre strength, well suited to massive engineering works, but somewhat too heavy for domestic architecture unless used in conjunction with lighter stone. As a road-metal it takes a high place even among basalts, and these as a class may perhaps be regarded as the most durable materials available. In this connection it may be interesting to note the "co-efficients of quality" quoted by Lieut.-Col. Sorsbie, R.E., in his "Geology for Engineers," from experiments made on a large number of road-stones;

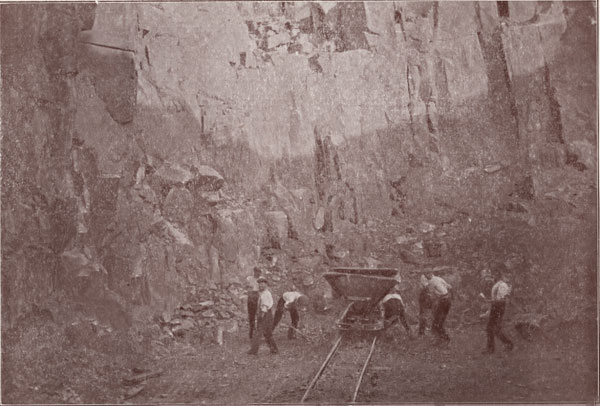

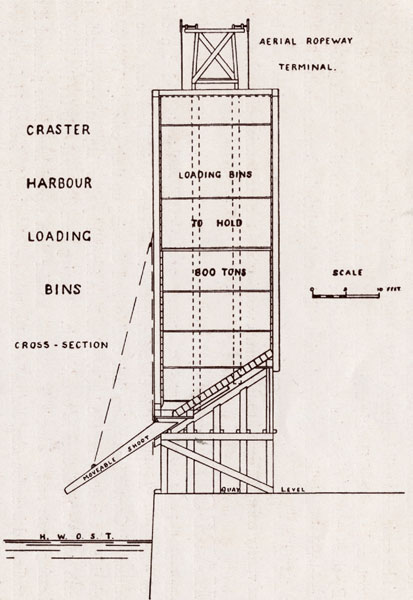

He also remarks in the same work that "Undoubtedly the best materials for producing the most durable metalling are basalts, diorites, and syenites," and "basalts are among the most efficient rocks for resisting crushing force." "Basalt weighs 171 to 181 tbs. per cubic foot, absorbs less than 4 ozs, of water per cubic foot, and is extremely durable.” "Among stones of the same kind, that which has the greatest specific gravity is invariably the strongest," and in this connection it is interesting to note that Craster Whinstone is a basalt weighing no less than 185 lbs. per cubic foot, while its absorption, after three hours' immersion, is hardly measurable. The attrition tests made by the Borough Surveyor of Hornsey, and quoted in a paper by Mr. J. A. Bean, C.E., F.G.S., County Surveyor of Northumberland, gave very similar results. These tests place the rocks in the following order- 1. The diabase and basalt group. Mr. Bean, in referring to the conditions of his own county, said : "The County of Northumberland is fortunate in providing one of the best materials for surface metal. Many of you will be aware of the great whin sill. . . ." "The rock is hard, generally tough, and superior to granite; moreover, it is not affected by weather." Mr. F. f . Edge, M. Inst. C.E., F.S.I., late City Engineer of Newcastle-on-Tyne, has specially inspected the quarries and reported on the stone as "excellent for roadstone, for setts, and for street channels. The quarry is well equipped, and the plant in good condition, well laid out for economical work and for distribution by sea." The quarries are equipped with steam rock drills of the "Hardy" type, drilling holes twenty feet deep. Black powder is used as the principle explosive in order to avoid the shattering effect on the stone resulting from the use of higher explosives such as gelignite. This is an essential feature of the working of the Craster quarries, since a considerable portion of the output is destined for the making of setts, curbs, and other rectangular blocks. The larger stones quarried out are used for these purposes, and the remainder of the output is loaded into wagons, hauled up a rope-incline, and tipped to supply the crushers. The whole of the crushing, screening, elevating, and conveying machinery is driven from a single power station by a Tangye suction gas plant of 81 H.P. The crushing plant consists of three Mason stone crushers with manganese steel parallel jaws, a cubing mill by Goodwin, Barsby & Co., and the necessary elevator, screens, bins, etc. Between the elevator and screens the stone passes through a revolving grill of parallel bars through which long flaky pieces are discarded. The same power-plant drives the rope-incline, drawing the wagons from the quarry-face, so that when the stone has once been loaded up no further manual labour is spent upon it until it reaches the bins as the finished product. An aerial rope-way is being erected, also to be operated from the same power-plant, to convey the stone from the crusher bins across the harbour at a high level to the loading bins on the south pier, and from these it will be run by gravity down shoots into the holds of steamers waiting alongside.

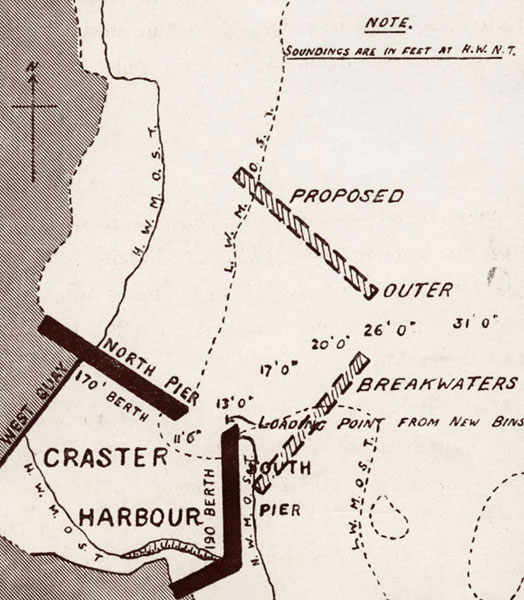

The remainder of the plant at Craster consists of cranes, steam road-wagon, engines and boilers, etc., a great variety being incidental to the quarry working and the construction of the harbour. Craster Harbour The harbour was designed by Mr. J. Watt Sandeman, M.Inst.C.E., and is situated at a cleft in the range of whinstone "heughs," this cleft forming a small cove, which had long been used by the fishermen of Craster for landing their catches and drawing up their cobles. The village is built on each side of this cove and the harbour has been formed by throwing out two concrete piers from the north and south sides so as to enclose it. Having been designed only for the accommodation of herring boats and cobles, it is naturally smaller than would have been planned if the whinstone traffic had been foreseen, but nevertheless steamers drawing 10 feet to 11 feet of water trade regularly, and at spring tides boats of much deeper draught can be accommodated.

It had for some time been foreseen that directly the original harbour contract was complete a scheme of extension would have to be planned and undertaken. This extension scheme is at the present time (1911) being set on foot. It consists in two breakwaters in deep water (see plan on page 14) from the north and south sides forming an outer harbour into which the present harbour will open, the objects being to improve the shelter in the present harbour, to provide a deep-water sheltered swinging space for large steamers outside, and to enable the present south pier head to be used as a berth where ships can lie under the new rapid-loading bins in all weathers, and be loaded with stone and sent to sea in the shortest possible space of time. The present harbour entrance faces north-east, from which direction it is partly sheltered by an outlying reef of rocks running parallel with the shore. The entrance to the outer harbour will face east by south, and consequently when that is completed the inner or present harbour will be almost perfectly enclosed.

Character of the Output The output of the quarries consists mainly of machine-broken road metal and paving setts, but chippings, hand-broken macadam, and dressed curbs and building stone are also frequently exported, and there is also a considerable trade in rough whinstone blocks for supply to workhouses, etc. The machine-broken stone is automatically graded in all sizes up to 2½ inches, this large size being much favoured in the North of England where it is largely used for tar macadam and general road maintenance, and produces excellent roads. Setts are stocked in the 4"x 5", 3"x 5", 4" cube, and many other sizes, and are despatched by sea or rail. Extent of Market The Craster Whinstone Quarries have three important advantages. (1) Only the most modern plant has been installed, (2) the quarries adjoin the harbour, and (3) Craster Harbour is nearer London than any other English exporting point. It is therefore claimed that Craster Whinstone can be supplied at rates lower than those necessary to produce and transport any other first-class road-store to destinations on or near the Thames or East Coast.

The most serious competitors of Craster Whinstone will be the Continental road-stones produced by labour at less than half the English wages, and partly handled by female labour at still lower rates. By the use of the most perfect plant, and by reason of Craster's economic position, it is expected that this handicap will be overcome. Owing to these circumstances, and to the increasing preference that our local authorities are showing for British materials, the future of the Craster Whinstone Quarries seems to be very bright.

Published by McLaren & Prowde, Ltd, C1911 This brochure was passed on to the Craster Local History Group by Doris Clark, who received it from Lady Sutherland, who has also given her permission for its publication and the donation of the original to the Northumberland Archives at Woodhorn. A copy of this brochure can be downloaded here as a Word (.doc) file |

|

Home Programme Membership Archive War Memorials History Walk Miscellanea Links Contact Us